|

Robert

White Sr - The Blacksmith Story of a Colonial Blacksmith in VA This

Hypothetical Story took place starting in 1739 "...A

Blacksmith may have been Apprenticed or Indentured |

|||||||||||||||

| About the

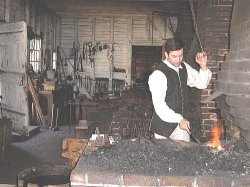

Blacksmith: The colonial blacksmith was one of the most important people in colonial America. The term blacksmith included the jobs of several specialists: making locks (locksmith), making gun barrels (gunsmith), shod horses (ferrier), but if one person performed all of these tasks, he was known as the village smithy or blacksmith. If the village lacked a dentist, the blacksmith could be called upon to pull teeth since he was certain to have a pair of pliers. The blacksmith was also responsible for making wheel rims, knives and tools, nails, and door hinges. He was also called upon to repair most anything made of metal. The blacksmith worked by heating the metal bars to 3000 degrees until yellow-hot in a forge with a raised brick hearth outfitted with bellows to feed its coal fire. With the help of his apprentices and journeymen, the smith then used sledge hammers weighing as much as 12 pounds to hammer the bar into shape. His other tools included smaller hammers, anvils, pliers, tongs, gloves and a heavy apron. 8 Years as a Blacksmith Apprentice: 5 Years as a Journeyman: |

|||||||||||||||

| The Story of My Early Life

I was born into the world on the 14th day of May in the year of our Lord 1739. My father was a tenant tobacco farmer and my mother helped in the fields when it came time for harvest as did I and my 4 brothers. When I was 9, my uncle, who owned the farm, died without heirs so my father inherited the small tobacco farm and the 2 Africam fieldhands. We weren't rich, but we were better off than before. My parents decided to send me off as an apprentice at the age of 11 to the village blacksmith.

|

Education

As is usual for people of my social class, and

being the third son, I didn't have too many prospects since my older

brother would inherit the farm someday, so my parents sent me off to be

an apprentice to Mr. Burrows, the blacksmith. There I learned,

over the course of 7 years, how to create useful things out of ore.

Although at first I learned the hard way that horses would kick if you

spooked them when shoeing them, I caught on. Apprenticeship was unpaid on the job training. |

||||||||||||||

|

|

|

||||||||||||||

| My Work

I know how to use fire to

mold metal into the objects needed for both the city folk here in

Williamsburg as well as for the farmers in the surrounding area.

Now that I am a full fledged blacksmith, I have enough experience that I

can finish jobs better and quicker than any other smith in Virginia, I

do believe.

|

My Family

When I was 22 years of age and having been a journeyman for four years at that time, and having saved enough pounds for a small dwelling near the Burrows foundry shop, I did ask Mr. Williams, farmer, for permission to marry his daughter, Miss Lydia Williams. With a small dowry payment exchanged, we wed 6 months later to the day.

Less than 3 years later, we had 2 daughters after losing one

son in the pains of birthing. By 1769, when Mr. Burrows passed,

I bought out his share of the business from his wife.

|

||||||||||||||

Master Blacksmith & Apprentices |

Made Nails etc... |

The Forge |

|||||||||||||

| My duty in life is to work with iron ore in its most

crude form as it comes from the foundry and then refine it into the

finest tools and horseshoes and other various implements to be found in

all of Virginia.

Products range from hoes and other farm equipment, shoes for horses and oxen to weaponry and arms of all sorts. |

We now have the money to live in some comfort and on

special occasions, we do feast.

I also frequent the local tavern where there is much talk of the politics of the day

|

||||||||||||||

Made Weapons |

Patriot or Loyalist? |

Made Weapons |

|||||||||||||

| My Thoughts on the Debate on Independence or Loyalty I have the privilege of having the contract for supplying the needs of the Virginia militia. My wife worries that it may be dangerous with the arguing between the Royal Governor and the House of Burgesses to be working for one side over the other. Yet, with the taxes and duties placed on my goods, though repealed, how can a working man not take sides as it affects his livelihood.

|

My Diary Entries

5 September 1763- I have now returned from service in the King's army against the papist French barbarians. I was assigned for the past 6 months to work in the service of the Royal Grenadiers in taking care of the horses and of repairing the cannons and wagons. Do they think I am a wheelright? I am glad that my apprentices were able to keep the business going. As my dear friend and partner Mr. Burrows is aging, the apprentices saved the business from falling apart. 17 June 1775 - I have benefitted from the support of clients now serving in the House of Burgesses. Unfortunately, everytime they are dissolved by the governor and then they reassemble, I must renegotiate all over. Yet, we are doing very well indeed. |

||||||||||||||

|

|

Time Line

|

||||||||||||||

|

|

|||||||||||||||

| Blacksmith

Tools & Products:

Items made for homes and other tradesmen Blacksmiths in Williamsburg fashioned items from iron and steel for the their fellow tradesmen to use in their work and also made things for household use. Among the tools blacksmiths used were the following:

With forge and anvil, hammer and tongs, blacksmiths made agricultural tools for farmers and iron rims for wheelwrights. They also repaired many iron objects used by Williamsburg residents. Their skills with vise and file served customers as diverse as the miller, saddler, coachmaker, and planter. For the householder, blacksmiths cast, bent, welded, and riveted fireplace racks, andirons, pothooks, locks, utensils, and decorative wrought iron. Coal fire heated iron bars A blacksmith's forge, like those at the James Anderson Blacksmith Shop, consisted of a raised brick hearth outfitted with bellows to feed its soft-coal fire and a hood to carry away the smoke. The forge heated bars of iron yellow-hot. With his journeymen and apprentices, the blacksmith used sledges weighing as much as 12 pounds to hammer the heated bars into various shapes. From steel, he made tempered cutting edges for axes and smooth faces for special hammers. Blacksmith Tools: In colonial America tools were very simple and therefore the skills necessary to perform the work of a blacksmith, for example, needed to be very sophisticated. The tools of a blacksmith were classified by their purpose, such as heating, holding, striking, shaping, and cutting, measuring, finishing, and tempering. The tool that was used the most by the blacksmith was the hammer. The hammer was used to either pound the metal itself or pound a tool that was placed on top of the metal. Other tools that were used were tongs, punches and wrenches. Tongs were used when metal was too hot to touch or if it was too short to pound with a hammer. The tongs were used as an extension for safety reasons. Tongs varied in size and shape and the blacksmith chose tongs depending on the job he was doing at the time. The anvil was also a very important tool because it provided the surface where the blacksmith could pound and shape his tools. Hardies were used to cut metal by putting a piece on top of it and then striking the metal with a hammer until the hardie pushed through the metal causing it to break. In addition to hardies, there were swedges and fullers which were identical tools used for shaping and were cut in half. The top one, the fuller, was flat so a hammer could hit on top of it. The bottom one, the swedge, fitted into the hardie hole, which was the square hole in the anvil. Another common tool used by a blacksmith was a vise, which was used for jobs such as holding metal in place, bending it, twisting it, and any other time the blacksmith needed another hand. Some additional tools were headers, swages, and files, punches as well as drifts. The shop of the blacksmith was always a place that was well visited and extremely busy. Due to the nature of the trade, everyone in the colonial villages eventually went to the blacksmith for some type of repair or a request for an order. Work at that time was bespoken, meaning that the blacksmith only worked if someone had made a request. Hinges, pots, teakettles, plow blades, etc. were the repairs that were routinely done in the shop. The shop consisted of one room that was fairly large in size with a big fireplace, referred to as the forge, and bellows that hung above the fireplace, for air supply. Charcoal provided fuel for the forge. Near the fireplace was a large bucket of water and the tools that the blacksmith used. In the middle of the shop stood the anvil. This was a large chunk of metal that was used to mold the iron in order to make the tools that were ordered. The shop was also very dark at all times so that the blacksmith could see what temperature the metal had. This was important in order to determine if the metal was soft enough or too soft. The forge is one of the essential pieces of a blacksmith's work because it is the fire place where the blacksmith heats up the metal. The forge is a container with some type of ventilation for air supply. The vent is connected to a pipe which again is connected to a manual blower. The manual blower will be operated by the blacksmith himself or his apprentice. The 1st Blacksmiths - During the 17th century colonists from all over Europe, in particular, England came to America to start a new life. Among them were workers that had skills and abilities that made them welcome in the colonial villages. The first blacksmiths to come to America were the armourers of the ships of the first colonists. Blacksmith Myth - Till this day there is a mistaken belief that blacksmiths spend all their time shoeing horses. This in fact is incorrect because the person who solely shoed horses for a living was called a farrier. Blacksmiths worked with iron to make or repair the tools that were necessary for farming, including horse and oxen shoes, and for the tasks in the shops of the villages. They also made the tools that were necessary for the daily tasks in the household, such as pots for the fireplace. When roads where established in America the blacksmith also started to repair wagons and carts. In order for the villages to grow it took a diversity of skills and talents and the blacksmiths represented such. Blacksmiths were very much valued and respected because during that time in America no village could have continued to exist without them. Many other trades could not exist before the blacksmith opened his business because he repaired the tools of all other people. Although blacksmiths started as the master of all trades, they became very specialized due to the increase in the need for blacksmiths in the villages. Regardless of the specialization among different blacksmiths there was one aspect of the trade that was followed by all smiths; the use of charcoal, basically all carbon, as the fuel for the fire in the shop. Charcoal was made from the abandoned hard wood that grew in colonial America and was therefore very cheap to acquire. It was also smokeless and it could burn at higher temperatures due to the carbon. Process of Shaping Iron: The iron that was used to shape the tools was heated till it became soft. After that point was reached the blacksmith would shape the iron into the form that was desired by pounding it. This process took a great deal of strength and skill due to the physical effort of lifting the hammer continuously and pounding the iron into a precise shape. If the iron would cool off during this step the blacksmith would have to re-heat the iron to continue shaping it. The iron needed to stay at a certain temperature because if it cooled off it might break and if it was too soft it was very hard to shape. If tools needed to be repaired due to a crack or a hole, the blacksmith would heat up the metal in the fireplace with a pair of tongs and evenly turn the metal until it became red-hot. Then the blacksmith would take the metal out of the fire and dip it in the barrel of water to cool it off. After a few seconds he would take out the metal and pound it on the anvil until the crack for example was fixed. If there was a hole in a tool he would heat up a small piece of iron and then seal the tool with it. Some of the iron pieces that the blacksmith worked with were extremely heavy so that he could not pick them up or move them by himself. Blacksmiths employed apprentices for additional help and to train them in the trade. Apprenticeships often lasted for several years. During this time the apprentice had to understand as well as study the different types of metals as well as the effect that temperature could have on them. |

|||||||||||||||

|

Example

of an Apprentice/Indenture Agreement

|

|||||||||||||||